Fig. 3. The MWCC expanded containment system.

The dual-shutoff interim system is designed for use in water depths up to 8,000 ft. It has the capacity to contain 60,000 bpd of liquids and 120 MMcfd of gas, with potential for expansion. It includes a 15,000-psi single-ram capping stack and dispersant injection capability.

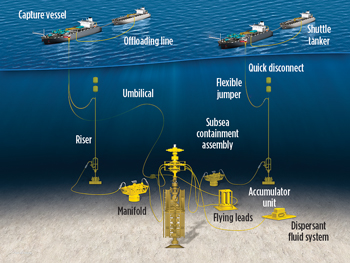

While the interim system is in place now, MWCC is working on an expanded system (Fig. 3), which is scheduled for launch in 2012. MWCC has contracted Technip to design dedicated subsea well containment equipment, including the containment assembly, manifold, control umbilicals, accumulator, dispersant injector, risers and flowlines.

When completed, the expanded system will be capable of operating in up to 10,000 ft of water with a 15,000-psi, three-ram stack and a dispersant injection system. It will have the capacity to contain 100,000 bpd of liquids and 200 MMcfd of gas, although using additional vessels could increase capacity.

The expanded system will have a new subsea containment assembly that will create a permanent connection and seal to prevent oil from escaping. The assembly, which is designed to prevent hydrates from forming, will have adapters and connectors so it can interact with the wellhead, BOP stack, lower marine riser package and/or casing and strings that are used by operators in the US Gulf.

Capture caisson assemblies will also be built to close off a damaged connector or leak that is outside the well casing. Once installed, the caisson will create a seal with the seabed to prevent seawater from entering.

Captured oil will flow through a flexible pipe to a riser assembly. If more than one capture vessel is required, a manifold will distribute oil from the subsea assembly to multiple riser assemblies. The risers and umbilicals will be able to quickly disconnect from capture vessels should they need to get out of the path of a hurricane.

The extended system will also include modular process equipment that will be installed on the capture vessels. The process equipment will separate oil from gas, flare the gas, and store oil until it can be offloaded to shuttle tankers.

Deployment of the system will begin within 24 hours of an incident. MWCC will make the equipment available to the incident operator, who is separately responsible for securing the required capture vessels.

原文地址:http://www.worldoil.com/May-2011-Need-Drives-Advances.html